Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

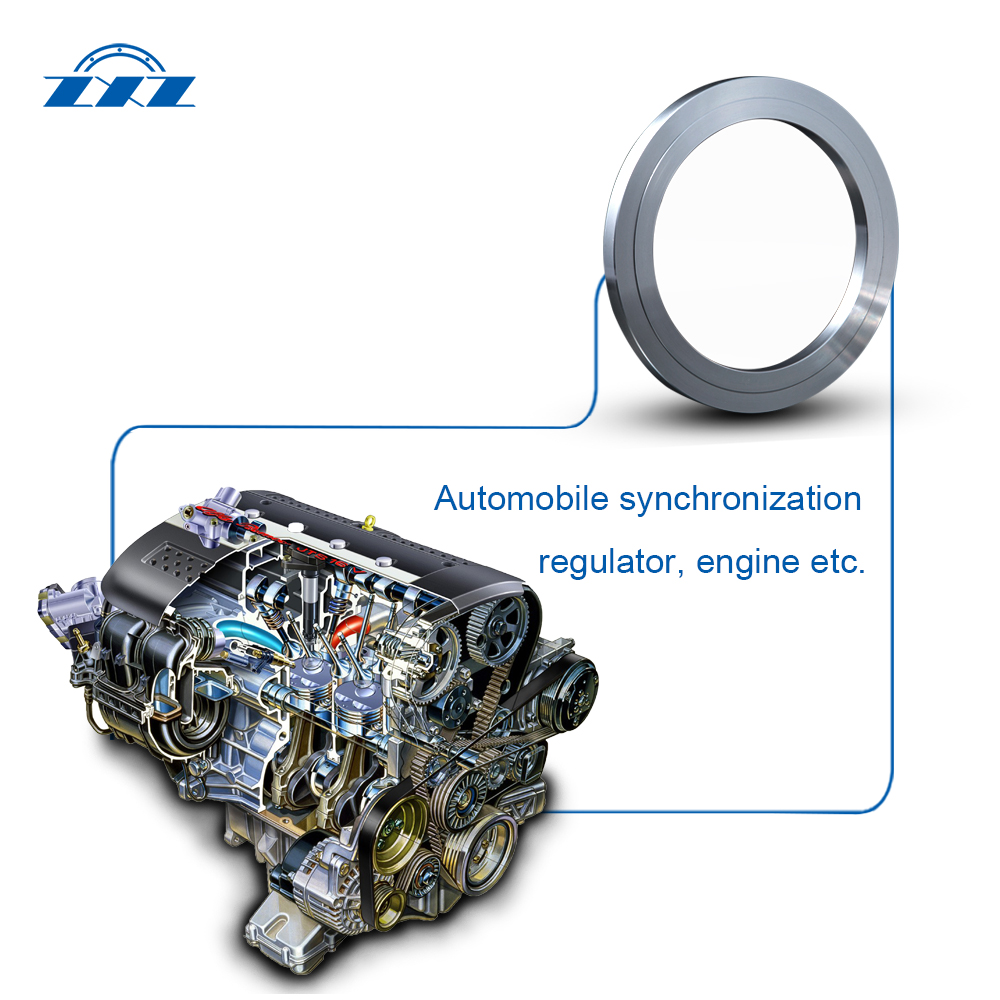

Model No.: balance shaft drive sleeve

Brand: ZXZ

Material: Steel

Type: Rim

Drive Wheel: 4WD

Wheel Hub Diameter: 16-20"

Finishing: Black

Wheel Accessories: Hub Ring

Spoke Type: Equal Diameter Spoke

Certification: ISO

Wheel Hub Brand: AMG

Packaging: Industrial package

Productivity: 1000000

Transportation: Ocean,Air

Place of Origin: China

Supply Ability: 10000000

Certificate: ISO9001,ITAF16949;ISO14001; OHSAS18000

Port: Ningbo Port,ShangHai

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA

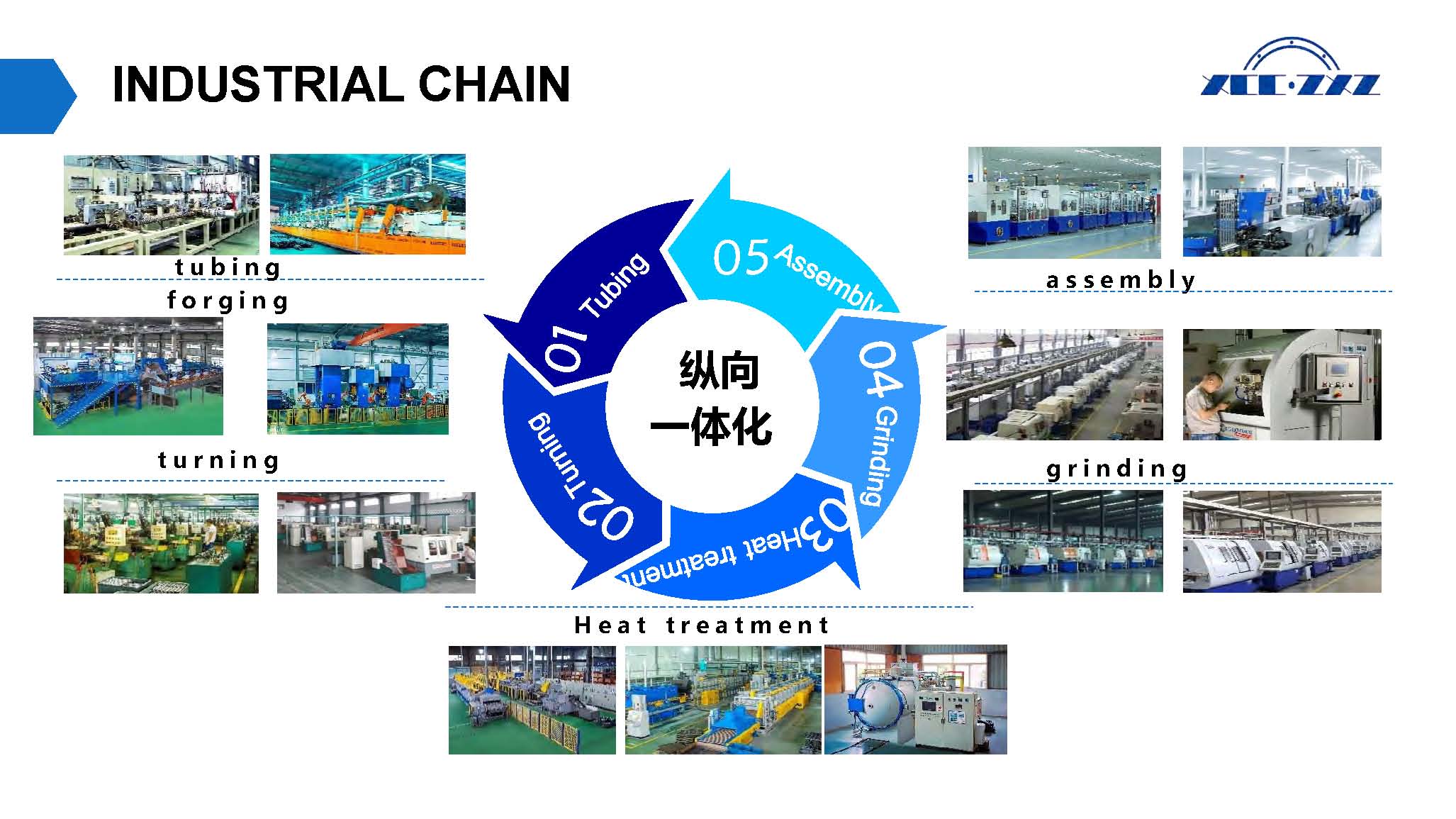

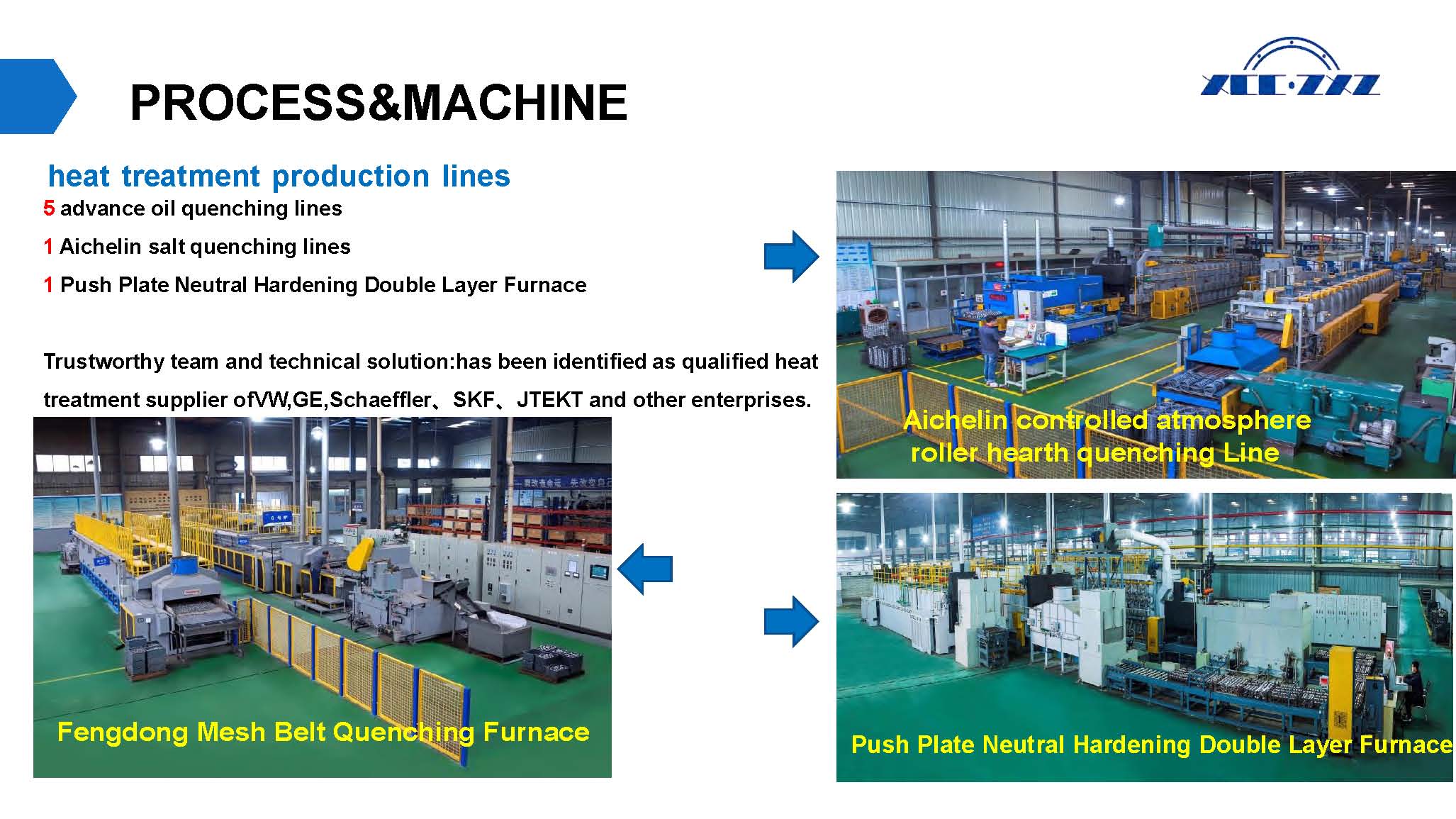

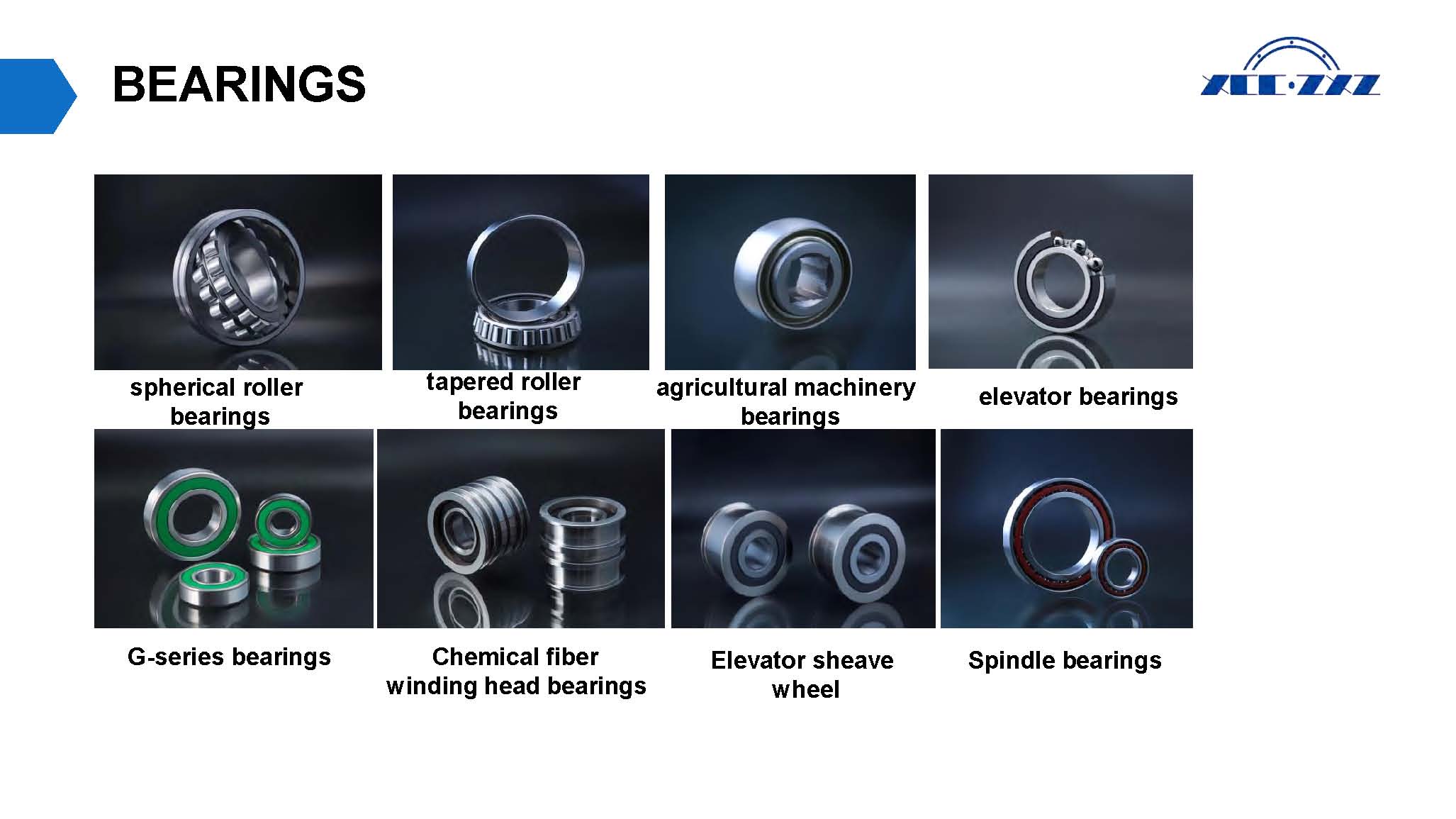

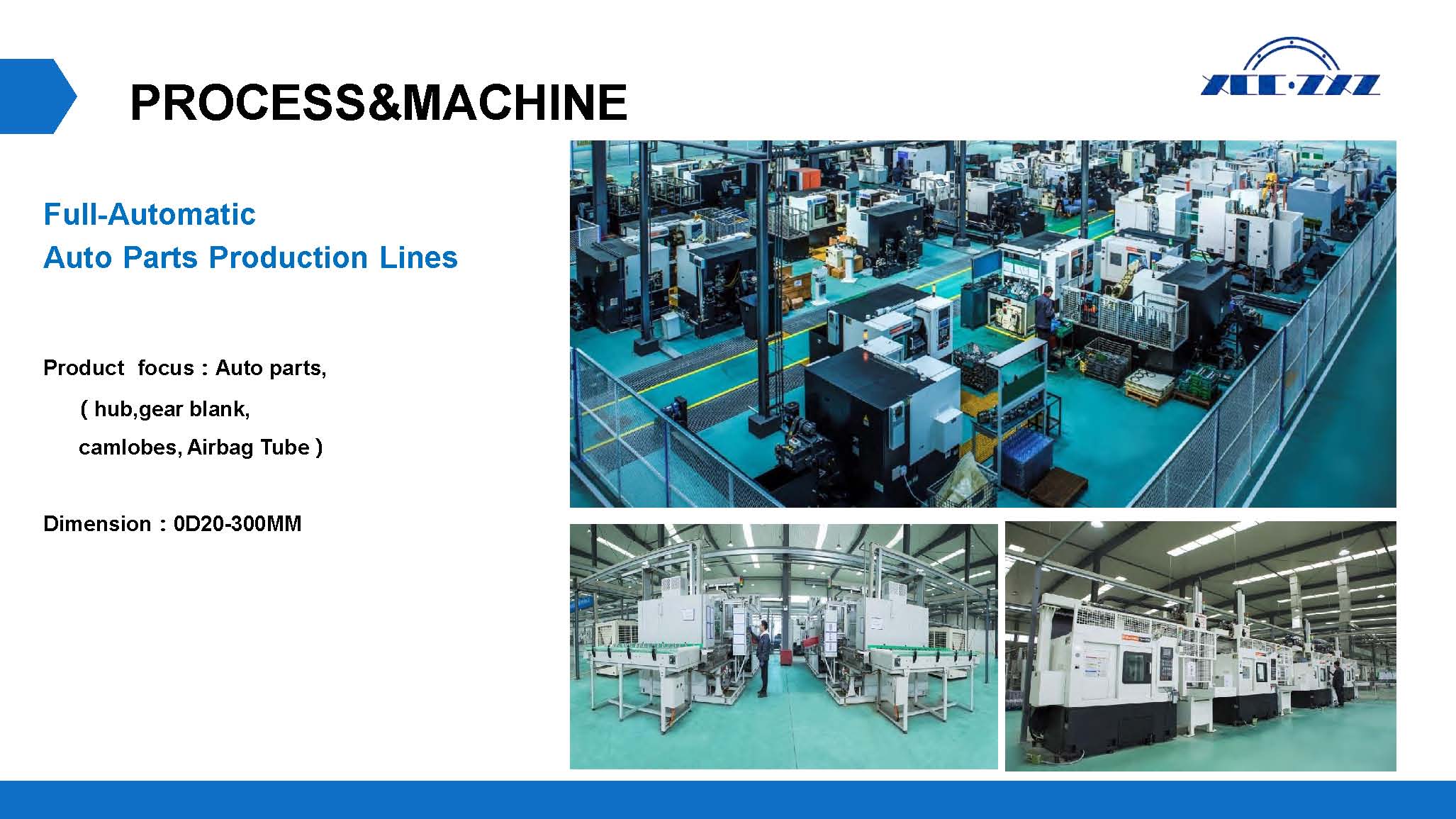

ZXZ build up entire bearing production line from steel tube, forging, turning, heat treatment to grinding and assembling after 10 years effort; high quality bearing rings which do heat treatment already provide for top 5 bearing manufacturer worldwide, production capacity reach 200 million sets annually; adopt full automatic CNC grinding and assembly line, benefit from big amount of advanced manufacturing equipments, has ability to service for world class level customers.

ADCANTAGES: Use Swiss Hateubr high-speed forging equipment AMP30S, in order to avoid the risk of water caused cracks mounting with lateral unloading system on the equipment, has advantages of lower allowance, better parallel and concentricity, no end face burr and chamfer defects happened.

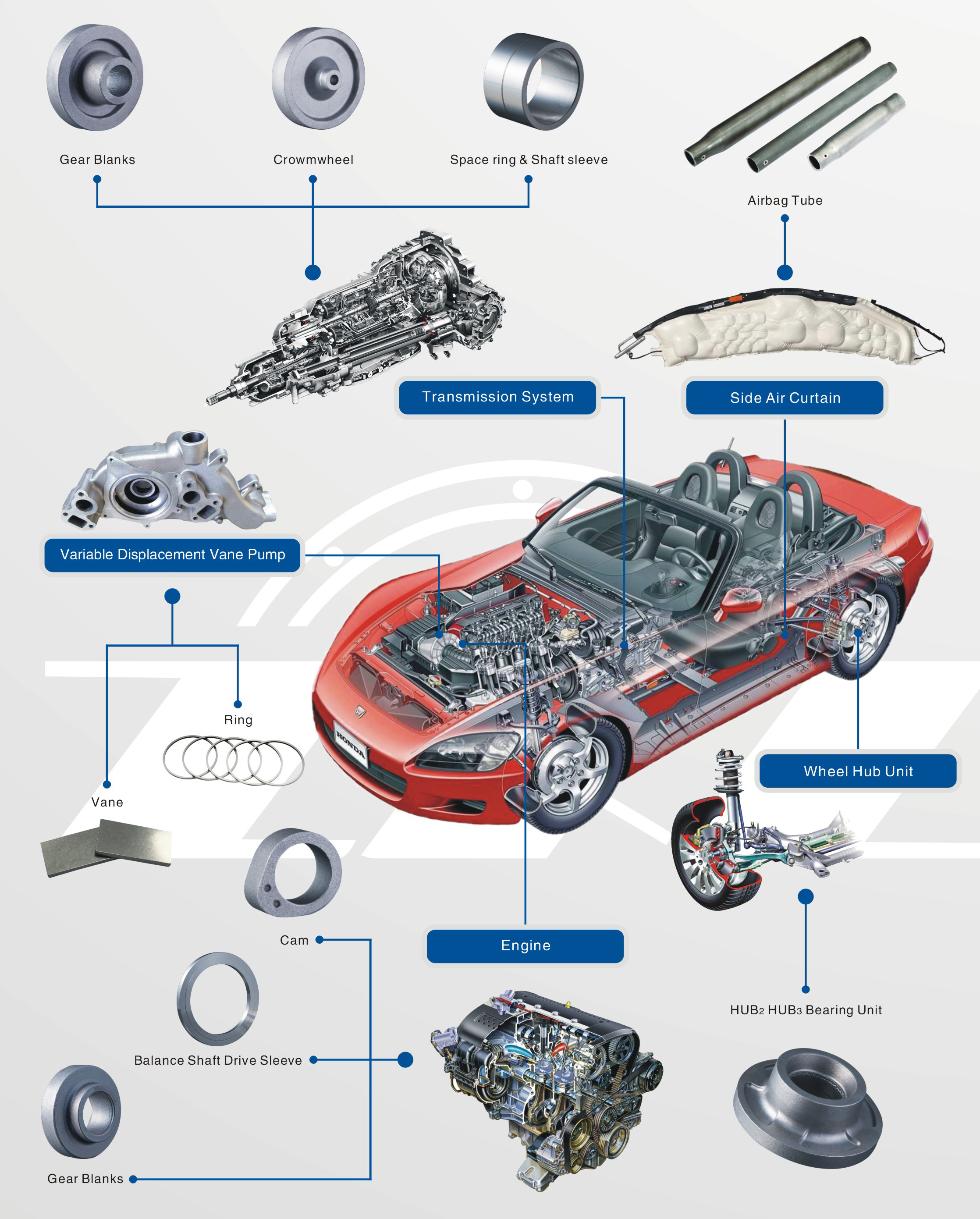

Automotive spare parts: Cam bit, 2nd.3rd generation Hub Bearing Unit, Gear blanks ,Gear sleeve, Vane ring, Space Ring and Airbag steel pipe.

ADVANTAGE:

The material selection of bearing components:

1. Rings manufactured by high-purity specialty quality bearing steel;

2. Steel balls are from famous brand manufactures, that effectively guarantee

materials and processing accuracy;

3. Using glass fiber reinforced nylon cages;

4. Sealed with high quality acrylic rubber;

5. Using synthetic oil (base oil) + Polyurea (thickening agent) Grease.

Design Structures:

1. Sealed with tri-lips medium contact structure

-- having a high sealing performance, and suitable for high-speed operation;

2. Using engineering plastic cages with oil reservoir structured

--effectively increase the lubrication capability of bearings;

3. Optimize the groove curvature of outer ring and the raceway of inner ring

-- adapt to high-speed performance and axial movement requirements.

Forgings are produced by 1000T+1600T electric screw press machine and Swiss Hatebur high-speed forging equipment AMP30S with medium frequency induction heating and full automatic operating by Robot for high quality assurance, lower allowance, advantages of materials saving and better metal streamline.

XCC specialized in the fields of bearings, bearing parts and Auto Parts manufacturing.

Intake and exhaust cam parts of Automotive spare parts :

CAM peach piece, oil pump CAM

APPLICATION :

The cam bit is application to automotive engine camshaft.

Performance: Intake .exhaust CAM parts

Performance: Intake .exhaust CAM parts

Type: Intake.exhaust CAM peach piece, oil pump CAM etc.

ADVANTAGE:

Use Swiss Hateubr high-speed forging equipment AMP30S, in order to avoid the risk of water caused cracks mounting with lateral unloading system on the equipment, has advantages of lower allowance, better parallel and concentricity, no end face burr and chamfer defects happened.

DIMENSION:

OD: 30mm-230mm

Product Categories : Auto Parts > Balance Shaft Drive Sleeve

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.